Reciprocating Friction Tester store|hfrr tester : purchaser A ball-on-plate reciprocating friction and wear test system, assessing the performance of both fuels and lubricants under boundary conditions. The HFRR is a ball-on-plate instrument used .

WEB2 dias atrás · Prêmios de até R$ 1.903,98 podem ser retirados em confiraloterias qualquer casa lotérica pelo país. Acima desse 📈 valor, somente nas agências da Caixa com a apresentação de comprovante de identidade original, CPF e recibo da aposta original. 📈 Valores acima de R$ 10.000,00 só ficam disponíveis na conta do ganhador dois dias .

{plog:ftitle_list}

WEBfmem A cross-platform library for opening memory-backed libc streams. This library was written for Criterion to implement stringification functions for user-defined types.

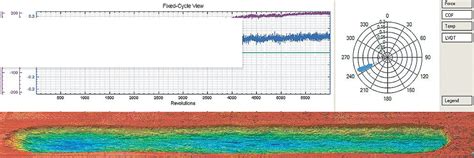

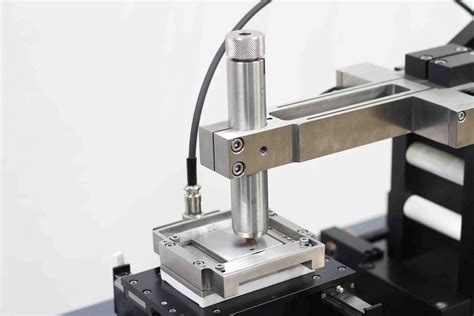

Evaluate fuel lubricity, predict the performance of additives, and study friction wear with our HFRR high frequency reciprocating rig. This next generation Rtec Instruments HFRR testing .Using various sensors it measures friction, wear, and adhesion of any reciprocating .Using various sensors it measures friction, wear, and adhesion of any reciprocating test setup with ease. The patented in-line 3D profilometer automatically measures topography change during the test. The module .Fretting Voice Coil. 10 µm-2.8 mm stroke, up to 300 Hz frequency. MFT-5000 Tribometer for nano, micro and macro range to study friction, wear, tribology testing, hardness of coatings, .

The High Frequency Reciprocating Rig (HFRR) is a microprocessor-controlled reciprocating friction and wear test system which provides a fast, repeatable assessment of the performance of fuels and lubricants.A ball-on-plate reciprocating friction and wear test system, assessing the performance of both fuels and lubricants under boundary conditions. The HFRR is a ball-on-plate instrument used .

The TE 77 High Frequency Reciprocating Tribometer is a well-known and versatile friction machine and research and development tool for the evaluation of lubricants, materials, .The High Frequency Reciprocating Rig (HFRR) is a microprocessor-controlled reciprocating friction and wear test system which provides a fast, repeatable assessment of the .

The TR 282 Series Reciprocating Friction Monitor is especially designed to study friction characteristics of materials. reciprocating engine is used to create a bidirectional sliding motion .a versatile wear and friction tester for every tribology lab. The highly modular POD-4.0 is a tribometer with many capabilities. Use it as a pin on disk, a linear reciprocation or a traction measurement tribometer simply by choosing the . The variation of friction force between upper test specimen and nether test specimen is very complicated on the reciprocating wear tester. There are many factors exerting influence on it. Based on the bench test, a system is developed for measuring the variation of the friction force between upper and nether test-piece. The acquisition of anolog signals is done .

The aim of this work is thus to develop a novel reciprocating tribometer and test method that enables friction and wear tests under low-speed reciprocatory sliding with contact pressures up to 90 MPa in a flat-on-flat .To facilitate the in-depth study of the tribological behavior of texture friction pairs in the process of reciprocating friction. The micro-displacement deformation output model of compliant mechanism is deduced using a new method for indirectly measuring friction coefficient through micro-deformation of double parallel four-bar compliant mechanism. Then, the whole structure .Polymer Testing 9 (1990) 195-211 Reciprocating Sliding Friction and Wear Test Apparatus S. M. H. Benabdallah Department of Mechanical Engineering, Ecole Polytechnique de Montrral, PO Box 6079, Station 'A', Montreal, Quebec, Canada, H3C 3A7 (Received 4 November 1989; accepted 2 December 1989) ABSTRACT As the friction and wear properties of polymers are .

The test rig can evaluate the performance of different surface treatments such as hardening, nitriding, and electroplating.This can provide valuable information on how different surface treatments can be used to improve the performance of mechanical components.. Some reciprocating sliding friction and wear test rig can also be used to study the effect of . The variation of friction force between upper test specimen and nether test specimen is very complicated on the reciprocating wear tester. There are many factors exerting influence on it. Based on the bench test, a system is developed for measuring the variation of the friction force between upper and nether test-piece.

It enables stable reciprocating friction testing. This device strokes up to 40 mm and is designed to be driven by the high speed vibrator for frequencies above 30 Hz. Data acquisition of RFW160 system uses National . Data acquisition systems normally store data at above 100

The vertical load, friction ball diameter and reciprocating movement frequency (friction speed) are selected as the experiment factors. The cutting tools was installed in the special designed fixture on a reciprocating movement wear test machine. The wear depth increases with the increase in the Z-load, ball diameter and frequency. The variation of friction force between upper test specimen and nether test specimen is very complicated on the reciprocating wear tester. There are many factors exerting influence on it. The more usual arrangement is Fig 1 The simple reciprocating friction and wear tester 0301-679X/80/010011"05 .00 1980 IPC Business Press TRIBOLOGY international February 1980 11 Moore and Noah - Friction and wear tester pneumatic loading of the test sample, as shown in Fig 3. Here, a pneumatic load cylinder under the action of air pressure .

linear wear friction testing

Ball-on-flat test: The ball-on-flat test is a method used to evaluate the wear characteristics and frictional properties of materials under controlled conditions. This test typically involves a spherical specimen (the ball) making contact with a flat surface, allowing for the study of tribological interactions, including wear mechanisms and friction coefficients.

The high-temperature reciprocating friction wear tester is mainly used for testing the friction properties of materials and surface coatings. The machine adopts automatic loading and magnetic drive, which can simulate the reciprocating movement of points, lines and surfaces. . friction coefficient and test temperature in real time. It can . 1.1 This test method covers laboratory procedures for determining the sliding wear of ceramics, metals, and other candidate wear-resistant materials using a linear, reciprocating ball-on-flat plane geometry. The direction of the relative motion between sliding surfaces reverses in a periodic fashion such that the sliding occurs back and forth and in a straight line.Historical/Traditional Test Geometry. The classic work of Thurston 1, Martens 2, Stribeck 3 and Hersey 4 were done using a journal-bearing geometry, which possesses all of the above requirements (Figure 3). An instrumented journal-bearing test allows for evaluation of the friction over a range of relative velocities and/or loads.

Aiming at the friction and wear experiment requirements for different solid materials under different conditions, a new reciprocating friction and wear tester is proposed.

In the lubrication state, graphite can also improve the friction performance. Graphite is prone to fall off during friction, resulting in the formation of pits on the wear scar surface. These pits can store more lubricating oil and improve friction performance under starved lubrication conditions [31].Bruker’s High Frequency Reciprocating Rig (HFRR) Module for the UMT TriboLab™ Mechanical Tester enables a versatile and cost-effective way to screen lubricants and materials at the benchtop scale. Traditionally, the . These pits can store more lubricating oil and improve friction performance under starved lubrication conditions [31]. Another important role of graphite is to improve the thermal conductivity of cast iron. Usually, friction heat can reduce the material's hardness and thermal fatigue properties, thus affecting the transition of the wear state . The friction and wear properties of PTFE and graphite-MoS2 filled PTFE composites were studied by using a reciprocating friction and wear tester under the different load, speed and wear time, and .

Based on the bench test, a system is developed for measuring the variation of the friction force between upper and nether test-piece and the real-time curve is made to provide the foundation for the further investigation. The variation of friction force between upper test specimen and nether test specimen is very complicated on the reciprocating wear tester. .Featuring a patented test principle, the SRV®5 tribometer allows for high-precision friction and wear tests of lubricants, materials, coatings and components. The SRV®5 tribometer offers a wide range of practice-relevant test concepts, even in its standard configuration with oscillation.

Reciprocating friction tester. . PVA is also typical for its ability to store a significant amount of water or biological fluids and to act as a lubricant resembling the cartilage surface [22 .

TRB³ pin-on-disk tribometer is the industry standard for friction, wear, and lubrictaion measurement. Learn more about its features and specifications. . reciprocating), contact modes, speed, lubrication, materials, high temperature, humidity, etc. . . together with friction force and other testing data in real time. Calibrate TRB³ with . The initial decrease in friction in the reciprocating tests on 316L stainless steel, reducing ploughing friction through smoothing of surface asperities, was also observed in 10-cycle nano-scratch tests at 30 mN with a 3.7 μm radius diamond [9] (data converted to friction coefficient in Fig. 9) and in 1 N tests on copper with a 100 μm radius .

linear friction tribometer test

ForceBoard™ is the world's no1 friction tester for unrestricted static and dynamic coefficient of friction measuremens for single or multiple stroke friction testing of materials, surfaces and components. It is very easy to use via the included Windows user interface and highly robust with zero maintenance requirements. We know the feeling of being kept in the dark when it comes .

Typical experimental results obtained with the computer-aided friction tester are presented for a thermoplastic sample rubbed against a steel slider with a polished surface in dry conditions. . Plane on plane contact and sliding reciprocating motion have been chosen. The design concepts are outlined and the specifications and characteristics .Friction and wear study of sliding surfaces plays a prominent role in the development of materials for various applications. The development of a low-cost multipurpose reciprocating tribometer at constant sliding speed to study the tribological properties of a material under dry, wet and high temperature conditions is presented in this paper. The tribometer has the ability of .

WEBThe latest tweets from @beccapires

Reciprocating Friction Tester store|hfrr tester